Ultrafast lasers are rapidly catching up with industry demand

Source: This website time:2021-06-04 browse:1374

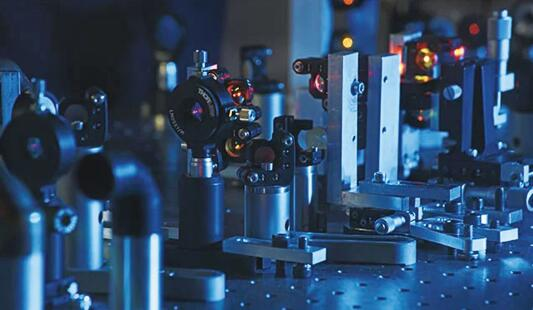

The pulse length of ultra short pulse lasers (commonly referred to as ultrafast lasers) can reach the picosecond or even femtosecond level. As a scientific research tool, the development history of ultrafast lasers has been several decades. With the development of ultrafast lasers, the fields of femtosecond chemistry, spectroscopy, and multiphoton imaging have also benefited greatly, making new research in neuroscience and quantum mechanics possible.

A series of factors such as technological development and the expansion of user base are driving the rapid growth of the ultrafast laser technology market. In the next five years, the market will grow at a compound annual growth rate of 16.6% - this forecast is made in consideration of the factor that the COVID-19 has led to the slowdown of production (source: Chromacity)

Now, ultrafast lasers have begun to surpass traditional research techniques. The commercial application of picosecond lasers has a history of more than 20 years. Subsequently, the manufacturing cost of ultrafast lasers has decreased and they can adapt to industrial demands, until recently when commercial applications have reached a critical point. Vincent Issier, Director of Production Line Management at Lumentum, a California based laser manufacturer, said, "In the past 5-7 years, picosecond lasers have been widely used. Prior to that, ultrafast lasers were the last choice

Nowadays, picosecond lasers are gradually becoming mainstream, partly because they can now join the competition for microfabrication solutions. They are also a new development direction in the industry, "said Vincent Issier. In 2016, Lumentum released the PicoBlade 2 ultrafast laser to explore this market. They have redesigned the technology to make it usable in smaller spaces and easy to integrate into industrial systems.

For a long time, ultrafast lasers have only been laboratory tools, but now the total cost of ultrafast lasers is low enough to arouse people's interest in their industrial application potential (Source: Chromacity)

Micro machining tools

According to a report by a market research company, the driving force behind the industrial ultrafast laser market is composed of several factors. Even considering the production slowdown caused by the COVID-19, the compound annual growth rate of the ultrafast laser market is still expected to reach 16.6% in the next five years. One factor is the emergence of large-scale demand.

Herman Chui, Senior Director of Product Marketing at MKS Instruments, said, "Consumer electronics are the real driving force behind the adoption of picosecond laser technology." MKS Instruments owns laser manufacturer Spectrum Physics, which can produce and manufacture picosecond laser devices. However, the demand for industrial ultrafast lasers in the automotive, bioimaging, and medical fields is also growing, which allows for the development of new manufacturing capabilities for industrial ultrafast lasers, such as laser processes with longer pulse widths or replacing other technologies.

Herman Chui stated that since Apple released the first generation iPhone in 2007, all electronic product categories such as tablets, AR/VR devices, and wearable medical devices have been commercialized. These devices are becoming smaller and more functional. Manufacturers need to be able to process materials such as printed circuit boards and OLED displays with more refined functions, but they must eliminate a large amount of heat transfer, as heat can damage materials, and ultrafast lasers are very suitable for such application needs.

Vincent Issier from Lumentum said, "In the past, mechanical processes were used, such as using a drill bit to drill lines and holes on the parts that make up electronic components. However, there were often situations where the drill bit size could not be further reduced. If the drill bit was worn or broken, the parts had to be replaced, increasing costs. In addition, maintenance can cause downtime and reduce the efficiency of the machine

The industry has been searching for ways to minimize production costs. The processing quality of ultrafast lasers plays an important role in this regard. By utilizing the appropriate performance of ultrafast lasers, such as wavelength, energy, pulse duration, and transmission optics, the heat affected zone in materials can be minimized, reducing fragment generation, recasting, discoloration, etc. This is a huge advantage, "said Vincent Issier.

Reliable laser

Of course, the industry must put effort into lasers to ensure that ultrafast lasers can compete with mature and sustainable mechanical microfabrication technologies. As demonstrated by Lumentum's redesigned product PicoBlade, the size of ultrafast lasers has been reduced, allowing for better integration into various manufacturing platforms and motion systems, which is one of their major advantages. However, Christopher Leburn, Commercial Director and co-founder of Chromacity, a Scottish ultrafast laser manufacturer, stated that improved reliability is also a major reason why ultrafast lasers have become industrial solutions.

Throughout the development history of ultra short pulse laser systems, it has been quite difficult to achieve reliable maintenance. As highly complex optical instruments, they require additional electronic layers or cooling processes to achieve consistent pulse quality or spectral stability, "said Christopher Leburn." Over time, improved laser architectures become more stable and manufacturing processes become more efficient

Herman Chui from MKS Instruments agrees: "It took us a long time to develop new methods for adapting these lasers to commercial applications. Many of these improvements have occurred over time and are not incremental functional improvements. They are improvements to existing laser architectures

In the box

Most industrial ultrafast lasers are designed based on the mature master oscillator power amplifier (MOPA) technology. There is an oscillator placed inside the laser of the amplifier, which is connected to the amplifier as a seed laser to increase the energy of the emitted pulses, and then laser processing is achieved through a standardized platform. Oscillators are usually based on optical fibers, while amplifiers can be based on optical fibers or solid-state crystals, depending on the final power output requirements.

Generally speaking, fiber amplifiers are a suitable choice when designing output power below 100W, while laser systems equipped with solid-state amplifiers can generate higher output power. Fiber amplifiers are also affected by nonlinear effects, such as stimulated Brillouin scattering, stimulated Raman scattering, and optical Kerr effect, which can interfere with power output. These unexpected effects are a major reason why instrument manufacturers often combine ultrafast laser systems with other systems for application.

Herman Chui stated that LiBo Spectral Physics Technology Co., Ltd., a subsidiary of MKS Instruments, has applied this combination architecture in its IceFyre picosecond laser, combining a fiber oscillator and a solid-state amplifier. This architecture allows the laser pulses to quickly switch from nanoseconds to picoseconds or femtoseconds according to demand. This has played a positive role in reducing costs, improving the performance of optoelectronic components such as diodes, and enhancing the cost-effectiveness of ultrafast lasers.

As a highly complex optical instrument, ultra short pulse laser systems have always faced the challenge of "difficult maintenance and operation". To achieve consistent pulse quality or spectral stability, electronic layers or cooling processes are required. However, improving the underlying architecture can make these systems more robust and durable, making them suitable for large-scale manufacturing (Source: Chromacity)

Christopher Leburn founded Chromacity while conducting laser research at Heriot Watt University in Scotland. The latest laser design launched by the company is an optical parametric oscillator (OPO) system, which uses gallium phosphide nonlinear crystals to generate picosecond pulses in the mid infrared region. Christopher Leburn introduced, "This oscillator is pumped by a high average power, 1 µ m wavelength light source based on a partially fiber, partially free space laser. These components are mounted on a single substrate, which contributes to the compactness and reliability of the laser system. The thermal efficiency laser system does not require water cooling

Faster pulse speed

With the development of ultrafast lasers in industrial processing, they have been used to process an increasing number of materials, including metals, glass, gemstones, and plastics. The unique characteristics of these materials and their different tolerances on laser pulses have prompted manufacturers to develop instruments capable of processing these materials. Herman Chui said, "R&D personnel in enterprises have been striving to find a balance between meeting customer needs and predicting market trends. We must focus on technology, design and produce products that meet market expectations

The new ultrafast laser from Libo Spectral Physics Technology Co., Ltd. emits picosecond pulses of harmonics in the ultraviolet and green wavelength regions of the spectrum. They also have some products that can emit femtosecond pulses. Shorter pulses can enable materials to better absorb light, resulting in shallower absorption depths. The thermal impact of femtosecond laser on materials is also lower than that of picosecond laser, with a smaller thermal impact area. However, when outputting the same power, the optical flux of femtosecond laser may be lower and the cost may be higher. Therefore, the parameters of the pulse, such as wavelength, shape, and type of pulse train, can vary greatly.

This is because the interaction between light and materials has been optimized, "Herman Chui said." Ultra thin glass cutting benefits from ultra short pulse lasers because you can achieve edge surface roughness of tens of nanometers without any post-processing. Taking flat panel display manufacturing as an example, this technological advancement helps to reduce its manufacturing cost

High power picosecond pulse laser cutting OLED display screen. The ultra short pulses of picosecond lasers can effectively perform finer processing on printed circuit boards and OLED displays, without conducting large amounts of heat and preventing component damage caused by this (Source: MKS Instrument Company)

Christopher Leburn from Chromacity said, "Femtosecond pulses can also expand the use of ultrafast laser systems. The company's femtosecond lasers have been used in semiconductor wafer inspection that requires high pulse repetition rates and low pulse energy. They also provide light sources that can transmit different wavelengths of 5 µ m-12 µ m, which are needed by environmental, defense, and security departments. Gases, liquids, and solids have very clear chemical characteristics in the mid infrared region, so applying these lasers in chemical analysis is very effective

Processing plastics and polymer materials with lasers emitting ultraviolet light generates less heat than lasers using infrared pulses. Lumentum's PicoBlade 3, released last year, offers a selection of ultraviolet and green bands in addition to infrared. Its computing power is four times that of previous products in the same series.

Customers require higher power to process materials, which can lead to higher production capacity, "said Vincent Issier. He believes that the number of industrial ultrafast lasers on the market will increase in the coming years. In addition, ultrafast lasers can also be used for other purposes, such as surface texturing, to create hydrophobic or hydrophilic functions on materials through laser processing.

Christopher Leburn from Chromacity has found that laser sizes are trending towards smaller sizes and should eventually reach a portable level. We have used our ultra short pulse OPO system to measure methane, ethane, and water vapor in the field, measuring chemical signals at a resolution of one billionth over a distance of 70 meters. This is an effect that traditional technology cannot achieve, "said Christopher Leburn." Creating a more compact ultra fast laser system is only a challenge in terms of time and resources, not physical aspects.